HDPE and MDPE pipes form the backbone of modern water infrastructure — delivering safe, durable, and high-pressure performance.

Yet during extrusion, manufacturers often face recurring issues: die build-up, melt fracture, unstable back pressure, and inconsistent surface finish. These problems not only affect pipe appearance but also reduce line speed, increase maintenance downtime, and raise energy costs.

For decades, fluoropolymer-based processing aids such as 3M™ Dynamar™ PPA have been used to ease these challenges. However, with growing PFAS restrictions worldwide, the pipe industry urgently needs a non-fluorinated, sustainable alternative — one that maintains or exceeds existing performance standards.

Why the Pipes Industry Is Moving Beyond PFAS-Based PPAs

PFAS (Per- and Polyfluoroalkyl Substances) are under growing scrutiny due to their persistence in the environment and potential health risks.According to the EU REACH Regulation and US EPA 2024 Roadmap, PFAS-containing processing aids will face progressive bans or strict reporting requirements.For manufacturers exporting pipes to Europe or North America, compliance is no longer optional — it’s a market necessity.

As a result, pipe producers are actively seeking PFAS-free polymer processing aids that can deliver the same extrusion smoothness and stability, without environmental or reputational risk.

Introducing the SILIKE SILIMER Series — A 100% Pure, PFAS-Free, Silicone-Based PPA

Developed by Chengdu SILIKE Technology, the SILIMER Series represents a major breakthrough in extrusion processing aids.

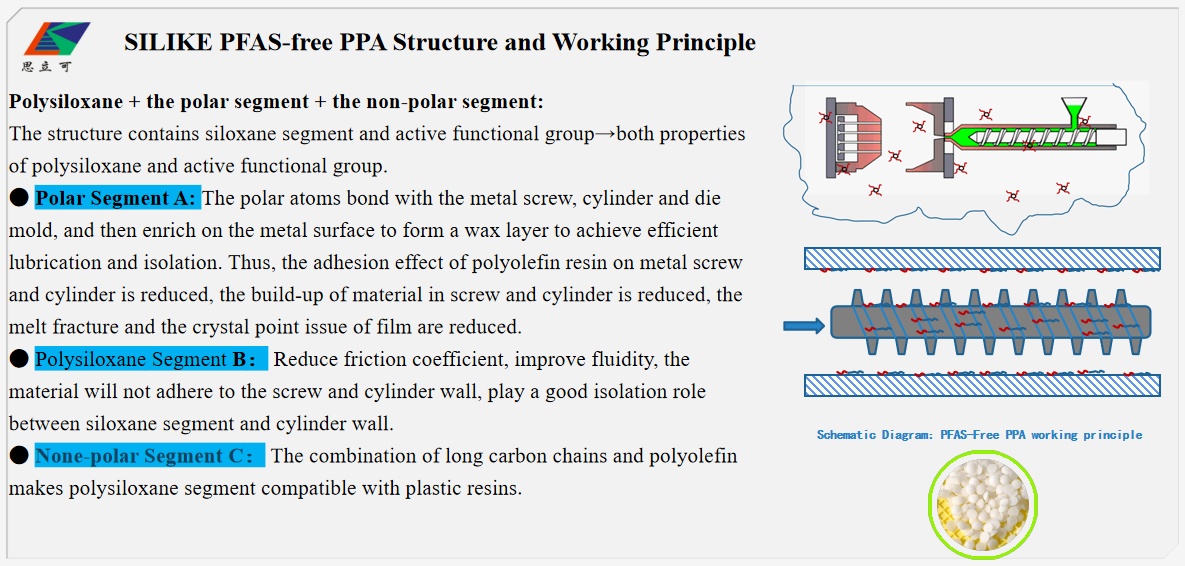

Unlike fluoropolymer PPAs, SILIMER silicon based plastics additives are based on a pure modified copolysiloxane molecular structure, combining the low surface energy of silicone with polar modified groups that actively migrate to metal surfaces.

Once at the die wall, these molecules form a stable lubricating layer, reducing melt friction, stabilizing shear stress, and minimizing die pressure — all without using any fluorine components.

How SILIMER series PFAS-free polymer processing aids (PPA) Works: The Science Behind PFAS-Free Performance

Solve Pipe Extrusion Challenges with PFAS-Free PPA Solutions – SILIKE’s Fluorine-Free Polymer Additives

SILIMER PFAS-Free PPAs are typically compounded into a masterbatch and added at low dosage levels (500–1000 ppm) to HDPE, MDPE, LLDPE, LDPE, PP, or PERT systems.

Even in small amounts, they provide major processing improvements:

Smoother polymer flow & melt uniformity

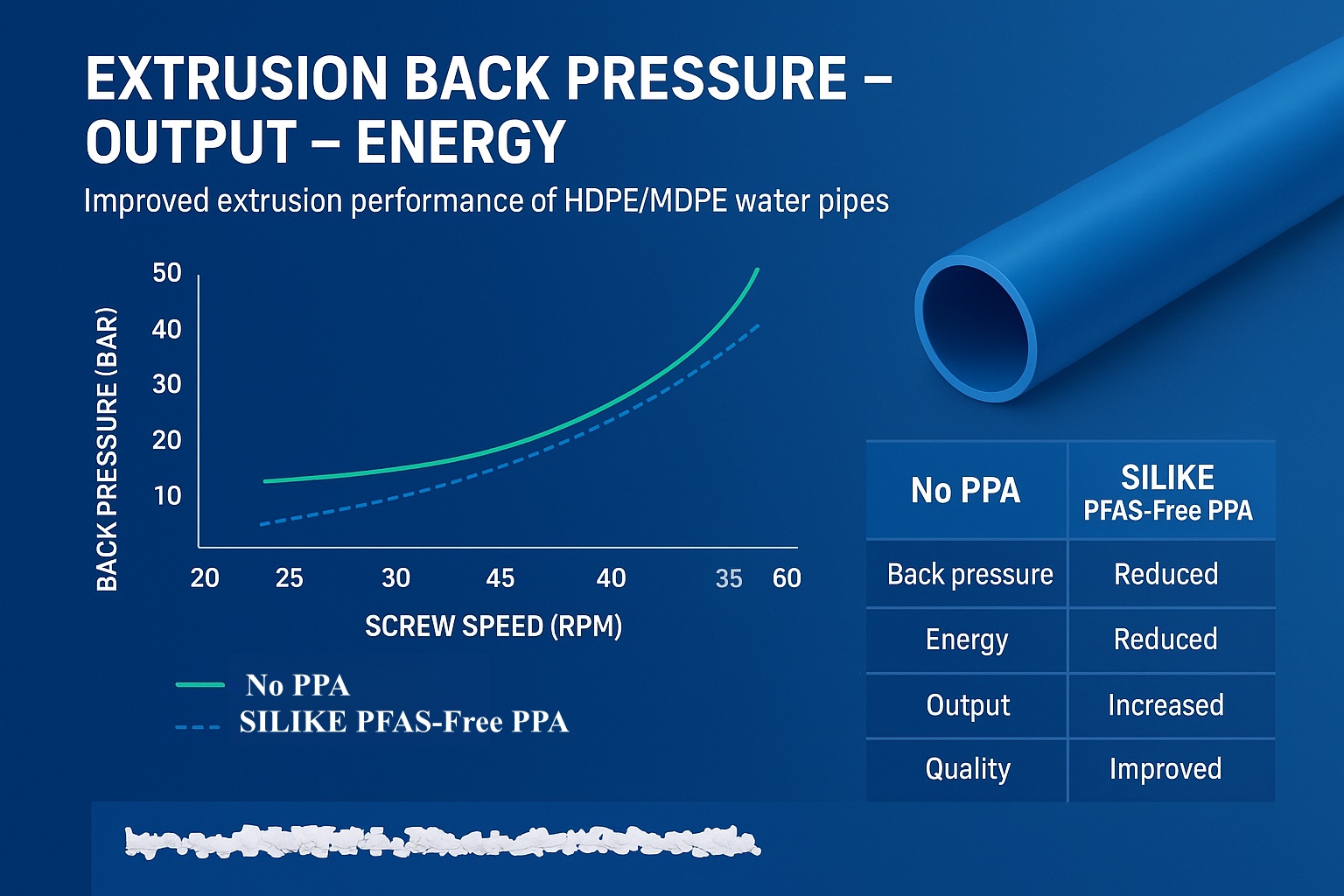

Reduced back pressure and torque

Elimination of shark-skin and die drool

Longer cleaning cycles and stable line speed

Higher output and lower energy consumption

Verified Results of Fluorine-Free Plastic Processing Additives in Pipe Extrusion Trials

According to customer feedback, their internal test results show that after using SILIMER PFAS-Free PPA, die pressure decreases by 10–20%, extrusion surfaces become smoother and more uniform, line speed increases by 10–15%, energy consumption is reduced by 5–8%, and the equipment cleaning cycle is extended up to three times longer than before.

Non-PFAS additive SILIMER 9400 — Tailored for HDPE & MDPE Pipe Extrusion

Within the SILIMER family, SILIMER 9400 stands out as a fluorine-free PPA additive specifically engineered for HDPE and MDPE pipe extrusion lines.

It delivers exceptional lubricity and processing stability under high shear conditions, ensuring cleaner dies, higher throughput, and a superior surface finish — all while being 100% fluorine-free and fully compliant with global PFAS restrictions.

Transitioning to PFAS-free extrusion no longer means compromising performance.

With SILIKE SILIMER Series pfas free ppa, the next-generation silicone-based alternatives to fluoropolymer PPAs/PTFE, manufacturers can now achieve faster throughput, cleaner dies, and full regulatory compliance — all within a sustainable, high-efficiency processing system.

SILIMER PFAS-Free PPA solutions transform HDPE and MDPE pipe production by addressing processing challenges and surface defects — including the elimination of melt fracture (sharkskin), enhanced melt flow, and improved surface smoothness for high-quality finished pipes.

Contact SILIKE today to optimize your polymer processing and enhance the performance and aesthetics of your pipe extrusion systems.

Also, you can reach out directly at amy.wang@silike.cn or visit www.siliketech.com to explore our eco-friendly pipe additive solutions.

Media Contact

Company Name: Chengdu Silike Technology Co., Ltd.

Email: Send Email

Country: China

Website: https://www.siliketech.com/